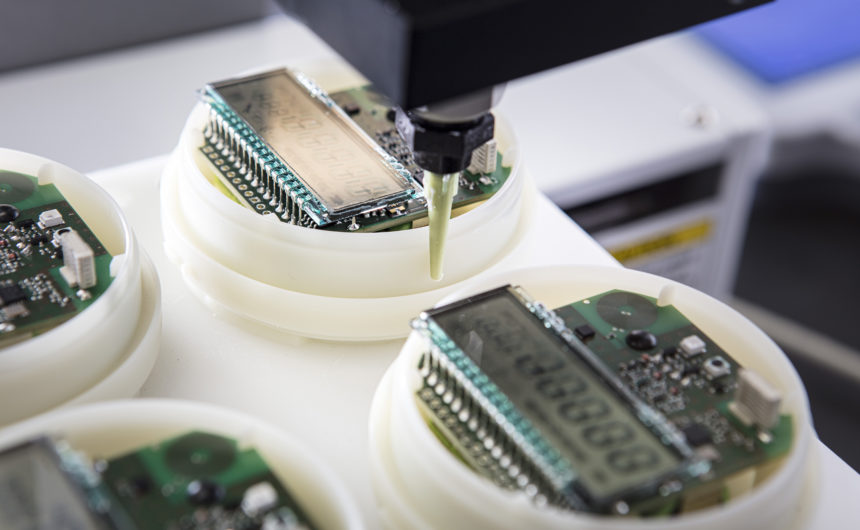

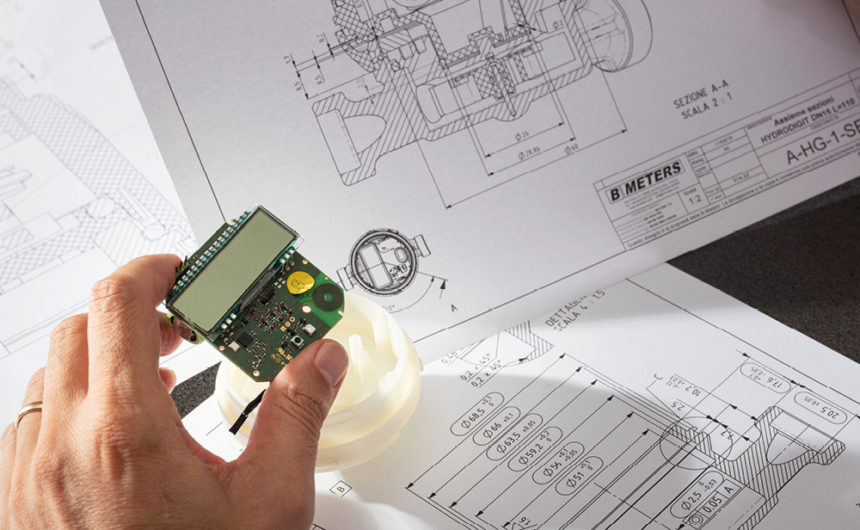

Societatea B METERS S.R.L. își desfășoară activitatea, ca o companie independentă și specializată, la nivel național și internațional, în domeniul măsurării consumului de apă și energie termică, propunând pe piață o ofertă amplă, cu soluții complete și integrate.

Contoare de Apă

Contoare de Energie Termică

Platformă smart care stochează toate datele pe cloud

Aduce sistemul de contorizare a apei și căldurii la un nivel superior mulțumită platformei web inovatoare care stochează automat toate datele citirii pe cloud.